Algeria

Andorra

Armenia

Australia

Austria

Azerbaijan

Bahrain

Belgium

Brazil

Bulgaria

Canada

Chile

Colombia

Croatia (Hrvatska)

Cyprus

Czech Republic

Denmark

Dominican Republic

Ecuador

El Salvador

Estonia

Finland

France

Georgia

Germany

Greece

Hungary

Iceland

India

Ireland

Israel

Italy

Japan

Jordan

Kazakhstan

Kuwait

Latvia

Lithuania

Luxembourg

Malaysia

Malta

Mauritius

Mexico

Moldova

Morocco

Netherlands

New Zealand

Norway

Oman

Panama

Peru

Philippines

Poland

Portugal

Puerto Rico

Qatar

Republic of Korea

Romania

Saudi Arabia

Serbia

Slovakia

Slovenia

South Africa

Spain

Sweden

Switzerland

Trinidad and Tobago

Türkiye

Ukraine

United Arab Emirates

United Kingdom

United States

Uruguay

Uzbekistan

Virgin Islands (U.S.)

हम आपको वे आइटम दिखा रहे हैं जो United States भेजे जाते हैं। किसी भिन्न देश में भेजे जाने वाले आइटम देखने के लिए, अपना वितरण क्षेत्र बदलें।

- GBP

- EUR

- USD

- CAD

- AUD

- USDT

- Deutsch

- English

- Français

- Latviešu

- Polish

- Türkçe

- हिंदी

- 日本語

- 中文

- Deutsch

- English

- Français

- Latviešu

- Polish

- Türkçe

- हिंदी

- 日本語

- 中文

Algeria

Andorra

Armenia

Australia

Austria

Azerbaijan

Bahrain

Belgium

Brazil

Bulgaria

Canada

Chile

Colombia

Croatia (Hrvatska)

Cyprus

Czech Republic

Denmark

Dominican Republic

Ecuador

El Salvador

Estonia

Finland

France

Georgia

Germany

Greece

Hungary

Iceland

India

Ireland

Israel

Italy

Japan

Jordan

Kazakhstan

Kuwait

Latvia

Lithuania

Luxembourg

Malaysia

Malta

Mauritius

Mexico

Moldova

Morocco

Netherlands

New Zealand

Norway

Oman

Panama

Peru

Philippines

Poland

Portugal

Puerto Rico

Qatar

Republic of Korea

Romania

Saudi Arabia

Serbia

Slovakia

Slovenia

South Africa

Spain

Sweden

Switzerland

Trinidad and Tobago

Türkiye

Ukraine

United Arab Emirates

United Kingdom

United States

Uruguay

Uzbekistan

Virgin Islands (U.S.)

- GBP

- EUR

- USD

- CAD

- AUD

- USDT

विवरण

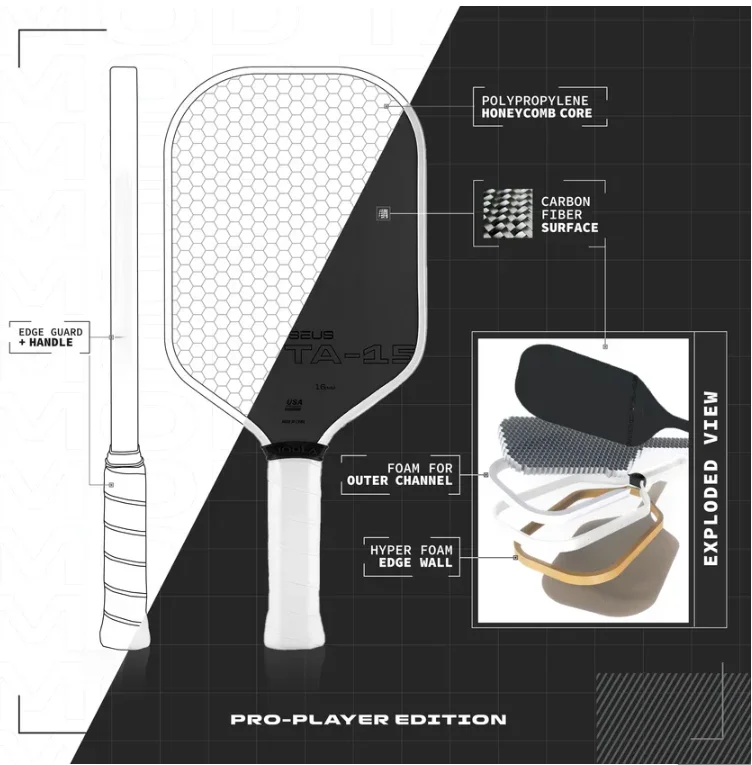

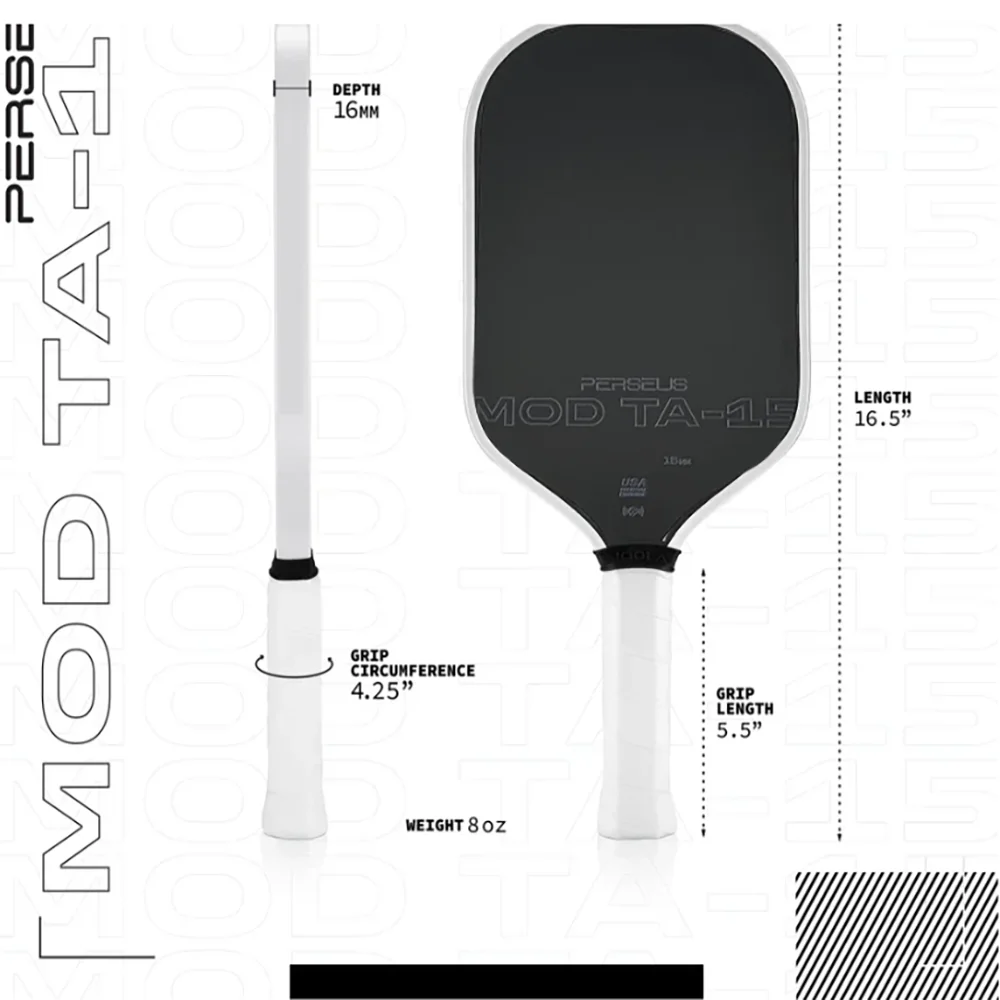

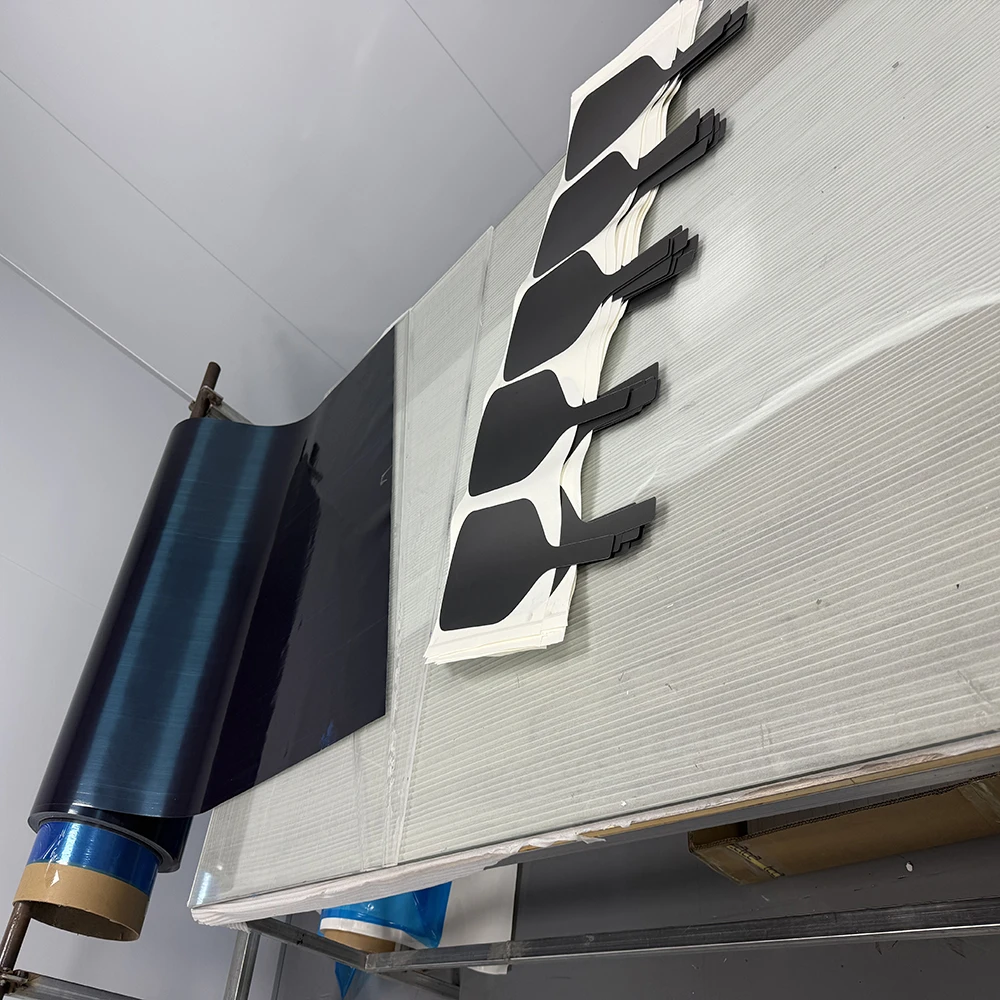

Built with a spotlight on solidity, MOD TA-15 paddles had been engineered to play an analogous each time you take the court The enhanced stability in every single paddle allows for exact shot placement and stepped forward dealing with Feel the arrogance to dominate each rally with a new and stepped forward core, mixed with Propulsion Core expertise to bring the ideal mix of strength and control MOD TA-15 expertise complements the Perseus’ signature sweet spot and Charged Carbon Surface to bring distinctive calories go back The MOD TA-15 paddle line adheres to the official performance standards of pickleball and is USAPA certified, empowering you to unharness your complete potential itemvaluePlace of OriginChinaGuangdongModel NumberHyi-16mm MOD MaterialCarbon Fiber, Toray carbon FiberBrand NameHYiAge GroupChildren, AdultsUsageEntertainment, Racing, TrainingPaddle Length (cm)41 Length(cm)14Weight (g)225g+/-5gProduct NameMOD TA-15 16mmMaterialToray Carbon FiberLogoAccept Customized LogoColorWhiteCore Material8mm PP Polypropylene Honeycomb Core with EVA Foam 16mm CoreFace MaterialVertical carbon fiber+horizontal glass fiber+vertical carbon fiberCertificateMeet USAPA StandardSize16*7 inchRZ/RT ValueClose 30/40 Notice: 1:If the link you notice allows you to place an order directly, we are able to replace the logistics fame for you within 24 hours on non vacation days and forty eight hours on holiday days 2:If you've customization needs, please contact customer service, The inside is packed with 8mm polymer honeycomb , Surrounded by way of a white EVA foam The outermost layer is a yellow foam encased in carbon fiber The manage is wrapped in carbon fiber material The honeycomb turned into coated with resin We observe resin to the honeycomb floor Then hide it with carbon fiber plates The composition structure of the carbon fiber plate consists of 3 layers The first layer is vertical Toray carbon fiber The second layer is a horizontal glass fiber The third layer is vertical Toray carbon fiber After the carbon fiber plate is glued to the honeycomb, it is put into the mould for thermoforming After 25 minutes of thermoforming, we are able to get a semi-finished 360-degree GEN3 pickleball paddle Next, we print the surface sample Assemble edge guard strips and GRIPS We end up with a carried out GEN3 pickleball paddle When glass fiber is added to the skin of the carbon fiber plate, paddle will have extra control and spin in use The EVA foam crammed propulsion core will make the paddle have extra powerful resilience GEN3 paddle will provide you with a good trip in pickleball video games Step1; Choose the paddle length and shapeThe USAPA typical stipulates that the sum of the length and width of the whole paddle can not exceed 24 inches 16 * 7 flat height form and 140mm grips length,suitable for forward attacking gamers with one or two hands, tending in direction of assault and balanced control, with good balance sixteen * 7 flat height form and 140mm grips size ,Suitable for forward and backward one passed attacking players, with a bigger sweet zone and better steadiness sixteen * 8-inch racket, suitable for defensive players, with excessive steadiness in ball control 16*7 inch fan-shaped peak and 140mm has lower wind resistance and is appropriate for backhand forward attacks, Step2; Choose the materialBeginners usally use fiberglass rackets, which frequently have inadequate rebound and rotation strength, and are at risk of breakage throughout cold pressing Most advanced gamers have started utilizing carbon fiber material and using thermoforming technology to produce it, which has nice resilience, friction, and service life Semi legit and professional gamers veritably have strict requirements for strength, rotational friction, and ball control The constitution from the core to the surface needs to be specifically personalized to realize a balanced point The length of the honeycomb core aperture impacts the pliancy and candy zone of the ending job The greater the honeycomb core aperture, the larger the corresponding candy zone, but the energy will be smaller Surface supplies are generally divided into three categories: glass fiber, carbon fiber, and Kevlar Among them, carbon fiber is divided into several classes in accordance with strength, namely T300, T700, T800, T1000, 3K, 12K, and 18K Different floor buildings also can convey assorted results Step3 Pre type The scorching forming process requires manually injecting foam into carbon fiber And wrapping it 360 levels in all directions to reinforce the overall sealing, rebound strength, and expand the sweet zone of the racket The handle after sizzling forming is also more sturdy Step4 Thermoforming Place the pre shaped honeycomb core and carbon plate into an aluminum mold and preheat it for 25 minutes The carbon fiber materials in the mould is often hot pressed at a extreme temperature of round 130 degrees until we have a 360 diploma integrated rough embryo Polish the carbon wire extruded after heating to make its total edges tender Step5 Printing Patterns The patterns on the racket are often published using UV, particularly carbon fiber materials If you would like maintain essentially the most primitive carbon friction, maximum will only decide to print the road sort The use of laser engraved patterns could cause significant damage to the skin of the racket If you like patterns with greater areas, to be able to maintain surface friction, you will choose to spray particle paint Step6 Packge the edge and grips Customizable color, material, and craftsmanship of the edge strips, as well as the color, material, and grace of the grids FAQ1 Q:Are you a producer or a trader ? A:We are a manufacturer, located on the 5th floor of Building A, Huaxia 3rd Road, Qiaotou Town, Dongguan City, Guangdong Province, China Dongguan Hengyi Sports Equipment Co, Ltd 2:We are an e-commerce entrepreneurial seller, are you able to provide me with any support? A:Our manufacturing facility may give a dropshipping service, serving different e-commerce sellers similar to Amazon Buydo LAZADA, EBAY, and so on We can also present instant sample delivery services, with bloodless pressing task sampling taking 3-5 days and scorching pressing process sampling taking 5-7 days Can produce a thousand hot pressed units consistent with day, using present molds Delivery within 3 days for less than a hundred models 3:Can you present comprehensive customization capabilities? A:We have ride in brand OEM and might customise the internal core and surface materials structure, pattern, edge strips, grip, and MOQ=1pcs in line with our wishes four Q:What materials do you usually use? A:Usually, we use Japanese Toray carbon fiber, which has advanced energy and put on resistance in comparison with T700 in the identical category If there are other materials requirements, we are able to do any customizationPowerful manufacturing process,Hot forming process, month-to-month manufacturing capacity of one hundred thousand units, bloodless pressing process five Q:what amenities do we provide? A:Accepted Delivery Terms: FOB,CFR,CIF,EXW,FAS,CIP,FCA,CPT,DEQ,DDP,DDU,Express Delivery,DAF,DES; Accepted Payment Currency:USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF; Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow; Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Hindi,Italian

समीक्षा

0 people rated this product

Timberline Market

Perseus 14mm MOD TA-15 Pro Player Edition GEN3 Propulsion EVA Foam Filling Core Pickleball Paddle Racket USAPA Approved

मुफ़्त शिपिंग और वापसी

QWQER Express,

QWQER Express, USPS,

USPS, DHL

DHL

Shopping security

- Safe payment options

- Secure privacy

- Secure logistics

- Purchase protection