Açıklamalar

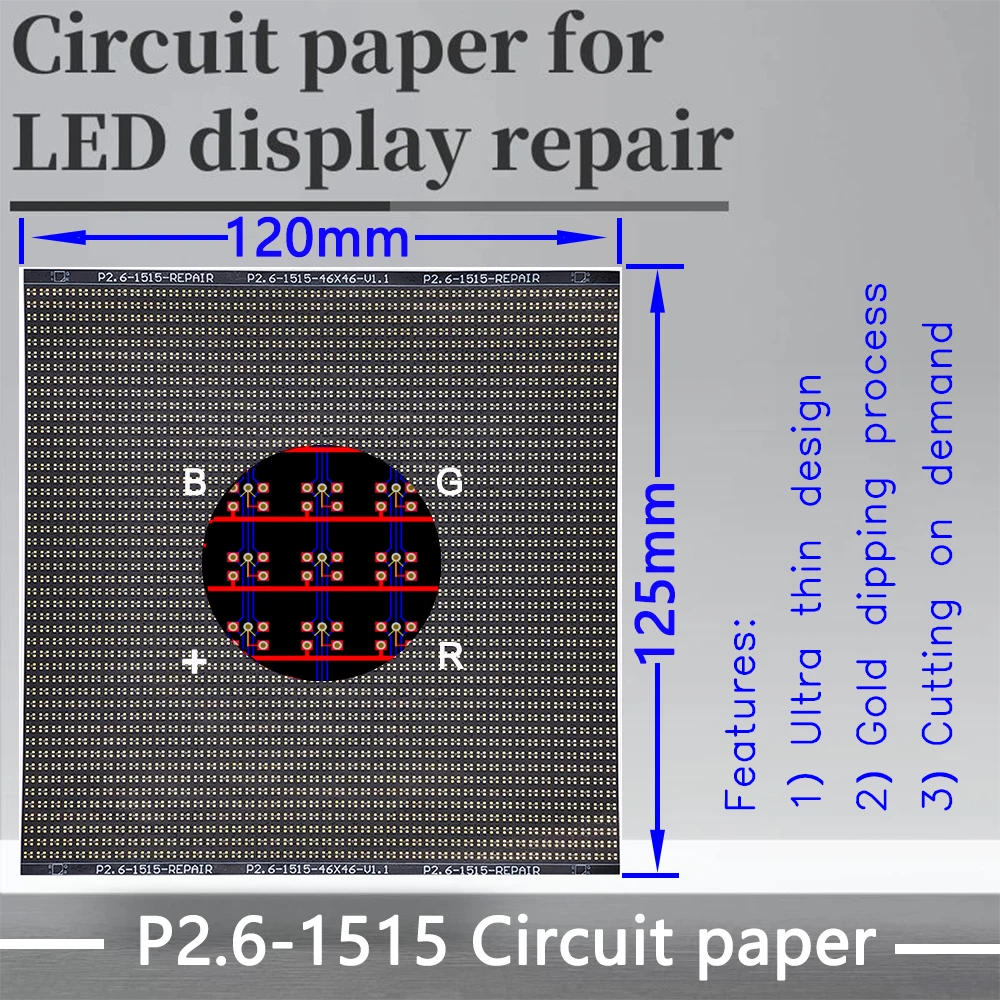

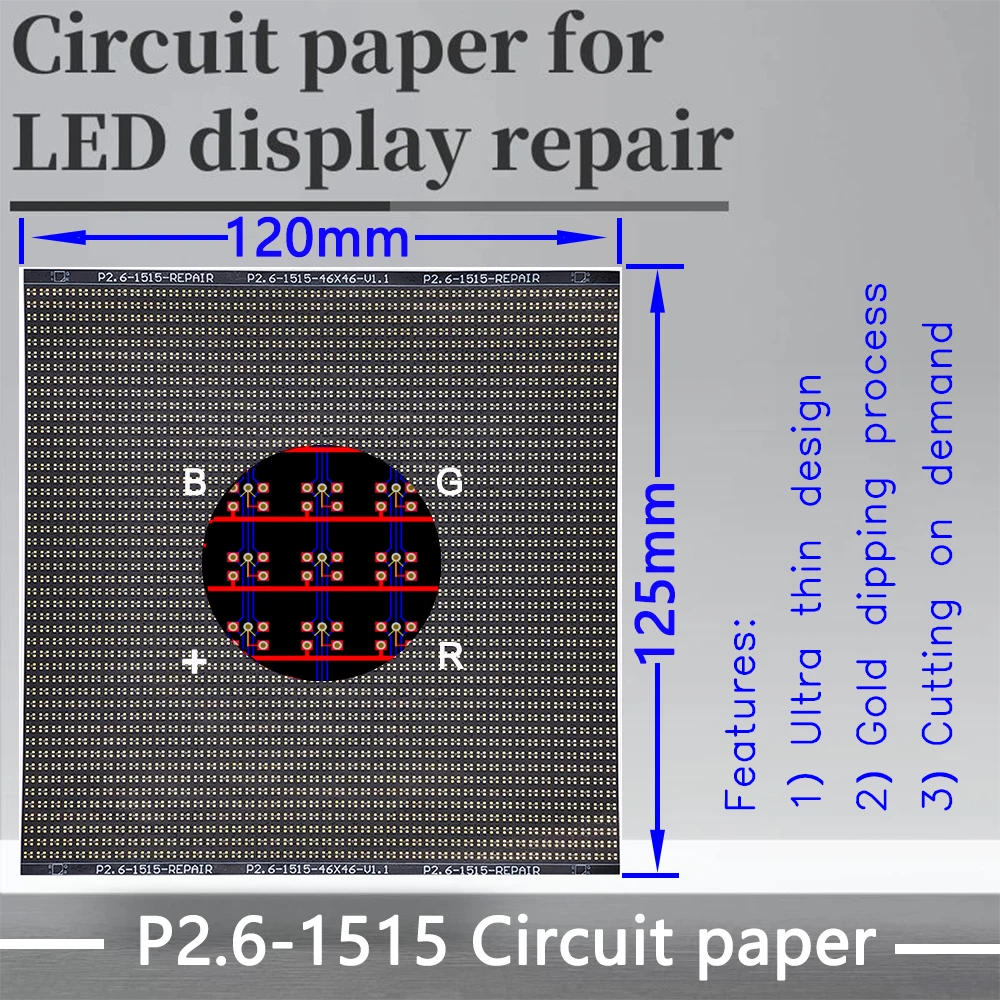

1、How to make your intellect up a circuit paper?1)The pixel pitch of the unique LED module must be in retaining with the circuit paper;2)The usual LED bead specs have to be in step with the circuit paper; 3)Some merchandise have variations between vertical and horizontal lamps (vertical lamps are more common, whereas horizontal lamps are much less common); If the unique LED module is a vertical lamp, the circuit paper for the vertical lamp ought to be selected. 2、Measurement method for the pixel pitch of LED module1) Measure the horizontal dimension(W) of the LED module using a caliper ;2) Count the number(N) of LED lamp beads in the horizontal route ;3) Calculation: Pixel pitch (P)=The module length (W)/The style of lamp beads (N) 【Numerical accuracy to 0】 3、Measurement formula for LED bead specification1) Measure the horizontal size (X) of LED beads using a caliper;2) Measure the vertical size (Y) of LED beads utilizing a caliper ;3) Calculation: LED bead specification=SMD (X) (Y); 4、The difference between vertical and horizontal lamp (as shown within the figure) five is the Circuit Paper?Circuit Paper is a type of double-layer bendy circuit board。Its thickness is just 0。6 of the Circuit Paper?Circuit Paper is composed of video display printing,base material, pads,holes, wires and decreasing line ect is the Circuit Paper used?The collision of LED display all the way through installation, disassembly and transportation can smoothly bring about PCB pad falling off. At this time, you need to use the Circuit Paper to repair PCB to use the Circuit Paper?First step, it's best to practice the ensuing upkeep devices and consumables: anti-static bracelet, soldering iron, scorching air gun, multimeter, tweezers, tin wire, solder paste, scissors, screwdriver, lamp beads, Circuit Paper, IC, and many others second step is to clean the broken pad, scrape the broken PCB pad with a knife blade, and wipe it with alcohol to prevent brief circuit with the Circuit Paper 1/3 step is to chop diverse sizes of Circuit Paper and tin on either side of the pad, so that the short circuit of the lamp foot can't be brought on by too much tin fourth step is to adjust the soldering iron temperature to about 320 ℃, clamp the tin-coated Circuit Paper with tweezers at the left hand, align it with the location of the soldering pad of the PCB lamp tube, press it gently on the pad, after which warm temperature it with soldering iron or hot air gun to make the Circuit Paper and the PCB pad totally fuse, listen in on the typical poles to be aligned;The 5th step is to light up the module, exhibit in full white, modify the brightness to the appropriate range for bare eyes by way of sweeping obliquely, weld the certified beads to the Circuit Paper, eavesdrop on the polarity course of the beads, and verify whether or not the pins are related with the multimeter before welding;Step 6: after the module examine is qualified, the lamp beads in the maintenance part should be full of glue. (indoor module does not want glue filling);

Gözden geçirmek

0 people rated this product

P2.6-1415-1515(VL) Circuit Paper,Vertical lamp which is usual,120X125mm ,Used for repairing damaged PCB pads

Ücretsiz kargo ve iade

QWQER Express,

QWQER Express, USPS,

USPS, DHL

DHL

Shopping security

- Safe payment options

- Secure privacy

- Secure logistics

- Purchase protection