Algeria

Algeria Andorra

Andorra Armenia

Armenia Australia

Australia Austria

Austria Azerbaijan

Azerbaijan Bahrain

Bahrain Belgium

Belgium Brazil

Brazil Bulgaria

Bulgaria Canada

Canada Chile

Chile Colombia

Colombia Croatia (Hrvatska)

Croatia (Hrvatska) Cyprus

Cyprus Czech Republic

Czech Republic Denmark

Denmark Dominican Republic

Dominican Republic Ecuador

Ecuador El Salvador

El Salvador Estonia

Estonia Finland

Finland France

France Georgia

Georgia Germany

Germany Greece

Greece Hungary

Hungary Iceland

Iceland India

India Ireland

Ireland Israel

Israel Italy

Italy Japan

Japan Jordan

Jordan Kazakhstan

Kazakhstan Kuwait

Kuwait Latvia

Latvia Lithuania

Lithuania Luxembourg

Luxembourg Malaysia

Malaysia Malta

Malta Mauritius

Mauritius Mexico

Mexico Moldova

Moldova Morocco

Morocco Netherlands

Netherlands New Zealand

New Zealand Norway

Norway Oman

Oman Panama

Panama Peru

Peru Philippines

Philippines Poland

Poland Portugal

Portugal Puerto Rico

Puerto Rico Qatar

Qatar Republic of Korea

Republic of Korea Romania

Romania Saudi Arabia

Saudi Arabia Serbia

Serbia Slovakia

Slovakia Slovenia

Slovenia South Africa

South Africa Spain

Spain Sweden

Sweden Switzerland

Switzerland Trinidad and Tobago

Trinidad and Tobago Türkiye

Türkiye United Arab Emirates

United Arab Emirates United Kingdom

United Kingdom United States

United States Uruguay

Uruguay Uzbekistan

Uzbekistan Virgin Islands (U.S.)

Virgin Islands (U.S.)

United States ülkesine gönderilen ürünleri gösteriyoruz. Farklı bir ülkeye gönderilen ürünleri görmek için teslimat bölgenizi değiştirin.

- GBP

- EUR

- USD

- CAD

- AUD

- USDT

- Deutsch

- English

- Français

- Latviešu

- Polish

- Türkçe

- हिंदी

- 日本語

- 中文

- Deutsch

- English

- Français

- Latviešu

- Polish

- Türkçe

- हिंदी

- 日本語

- 中文

Algeria

Algeria Andorra

Andorra Armenia

Armenia Australia

Australia Austria

Austria Azerbaijan

Azerbaijan Bahrain

Bahrain Belgium

Belgium Brazil

Brazil Bulgaria

Bulgaria Canada

Canada Chile

Chile Colombia

Colombia Croatia (Hrvatska)

Croatia (Hrvatska) Cyprus

Cyprus Czech Republic

Czech Republic Denmark

Denmark Dominican Republic

Dominican Republic Ecuador

Ecuador El Salvador

El Salvador Estonia

Estonia Finland

Finland France

France Georgia

Georgia Germany

Germany Greece

Greece Hungary

Hungary Iceland

Iceland India

India Ireland

Ireland Israel

Israel Italy

Italy Japan

Japan Jordan

Jordan Kazakhstan

Kazakhstan Kuwait

Kuwait Latvia

Latvia Lithuania

Lithuania Luxembourg

Luxembourg Malaysia

Malaysia Malta

Malta Mauritius

Mauritius Mexico

Mexico Moldova

Moldova Morocco

Morocco Netherlands

Netherlands New Zealand

New Zealand Norway

Norway Oman

Oman Panama

Panama Peru

Peru Philippines

Philippines Poland

Poland Portugal

Portugal Puerto Rico

Puerto Rico Qatar

Qatar Republic of Korea

Republic of Korea Romania

Romania Saudi Arabia

Saudi Arabia Serbia

Serbia Slovakia

Slovakia Slovenia

Slovenia South Africa

South Africa Spain

Spain Sweden

Sweden Switzerland

Switzerland Trinidad and Tobago

Trinidad and Tobago Türkiye

Türkiye United Arab Emirates

United Arab Emirates United Kingdom

United Kingdom United States

United States Uruguay

Uruguay Uzbekistan

Uzbekistan Virgin Islands (U.S.)

Virgin Islands (U.S.)

- GBP

- EUR

- USD

- CAD

- AUD

- USDT

Açıklamalar

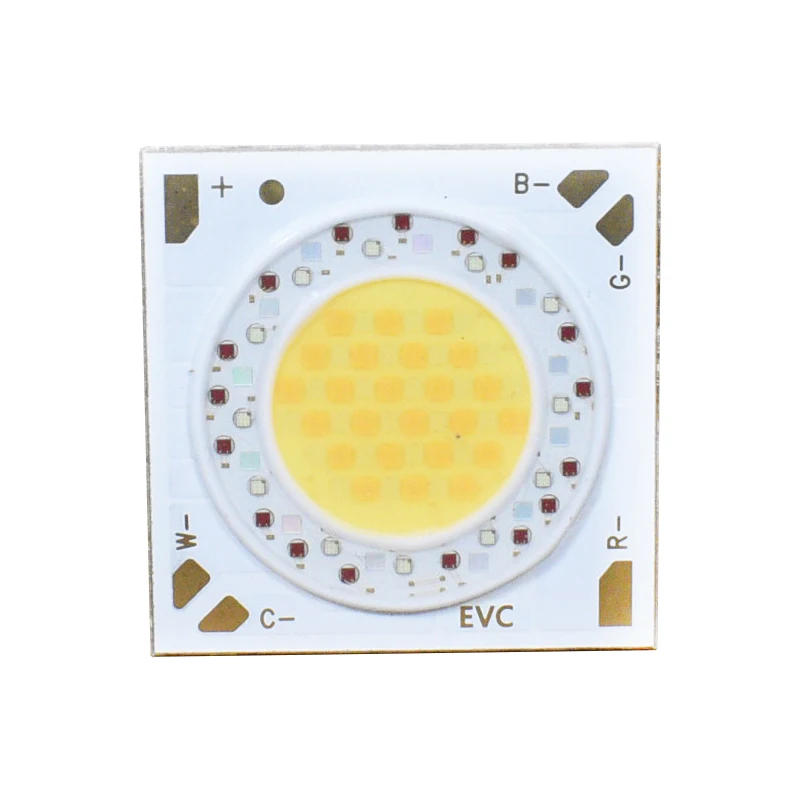

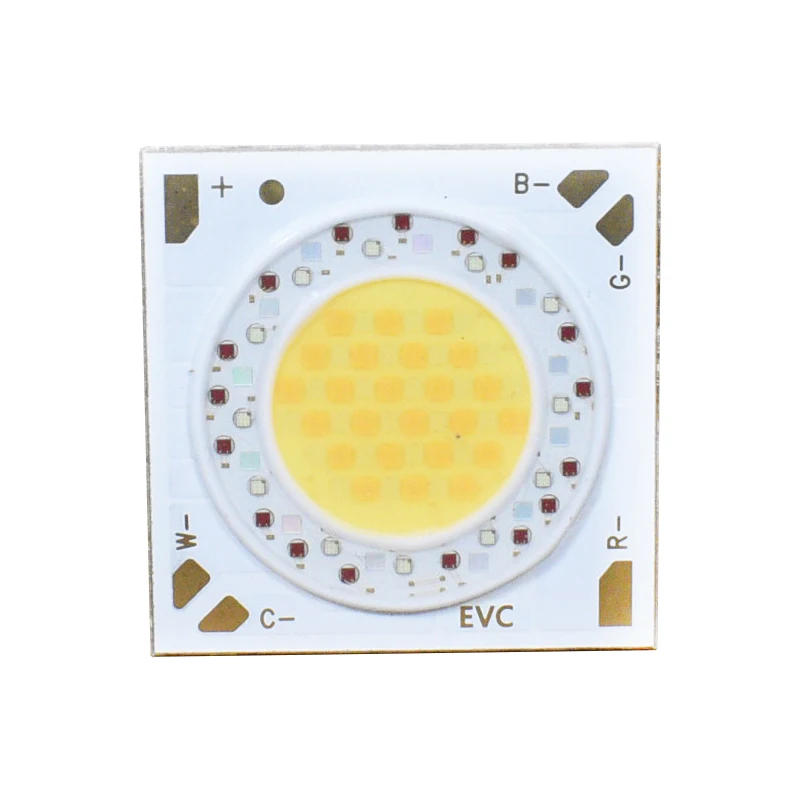

Mixing of any two colors with out colour stable or uneven spotA single colour is lit, calmly allotted in the light-emitting areaIt is handy for secondary optical matching of productsSuitable for clever controllable colourful lighting fixtures placesCompact 86WATT RGBWC COB chip with small luminous surface, excessive calories and excessive luminous flux Emitting color: Red / Green / Blue / Warm white / Cold white (RGBWC) LEDs type: Integrated COB chipChips: Bridgelux 2630 Viewing angle: 120 diploma Luminous efficiency: 115lm in keeping with watt (warm white); 125lm in line with watt (cold white) CRI: 90Ra for Warm white / Cold white Base material: The mirror aluminumChip thickness: 1 LED junction temperature: 125° LEDs arrangement See desk Input current for RGB colors: 350-400mAInput current for WW/CW colors: 700-900mA LED integrated board input voltage: See table ESD: 2000V Outer dimensions: 24x24mmDiameter of light-emitting surface: Ø20mm Please hear for the ensuing conditions: 1) Do no longer gentle it without heatsink aluminum in every other case it is going to get damaged. 2) The LED board should be powered via way of constant recent LED utilizing energy shipping Storage: To keep away from moisture, we recommend storage situations for the unopened LED +5 ~ +30℃relative humidity <60%. LED ought to be used within 168 Hrs. of opening the package. Pleasemake certain to dehumidify and vacuum pack the remaining/ unused LED. Dehumidifying condition:+120℃±5℃ of 4Hrs. Effective age for the sealed led is one year. The soldering precautions: Soldering conditions: Reflow soldering is not counseled for this LED. If hand soldering,set sol-dering iron temperature at 350℃ and soldering time not More than 3 seconds, afterthe first soldering, ensure the substrate floor temperature returns to ambient temperaturebefore a moment soldering. Please. make sure when soldering, there isn't any external pressure on thesoldering surface and silicon batardeau (such as pressure, friction or sharp steel nails, etc.),to preserve faraway from gold cord deformation or dam-age and different abnormalities. If beyond recommendedconditions, we won't warrantly the LED stability, please do the chance analysis first. Duringassembly, please ensure that a reputable high quality thermal paste is applied and dispensed lightly overthe surface. While utilizing thermal pad (Heat Sink), make sure LED is firmly tightened and thereis no hole between surfaces. In such heat-media products, by way of a stress verify of at least500 volts. Anti-Static Measures: Please take ample measures to prevent electrostatic generation, reminiscent of wearingelectrostatic ring or anti-static fingerstall etc; any relative item like plantequipment, machinery, provider and transportation models can be related to dischargingunit/ ground. The ESD sensitivity of this productis > 1000V(HBM), after assembly the finallamp, please make sure you discharge Static Electricity by way of right ESD equipment. Temperature control: Drive this product at constant current. Output current fluctuate specs should beac-cording to the operational and varied conditions, as acknowledged in information sheet. Before usinga fixed voltage delivery or altered specifications in addition to recommended, please considerrisk factors.

Gözden geçirmek

0 people rated this product

Small 5 IN 1 RGBWC COB Photography LED Chip 86W Stage Light Source 90Ra for Video Spotlights Downlights Photographic Equipment

Ücretsiz kargo ve iade

QWQER Express,

QWQER Express, USPS,

USPS, DHL

DHL

Shopping security

- Safe payment options

- Secure privacy

- Secure logistics

- Purchase protection