Opisy

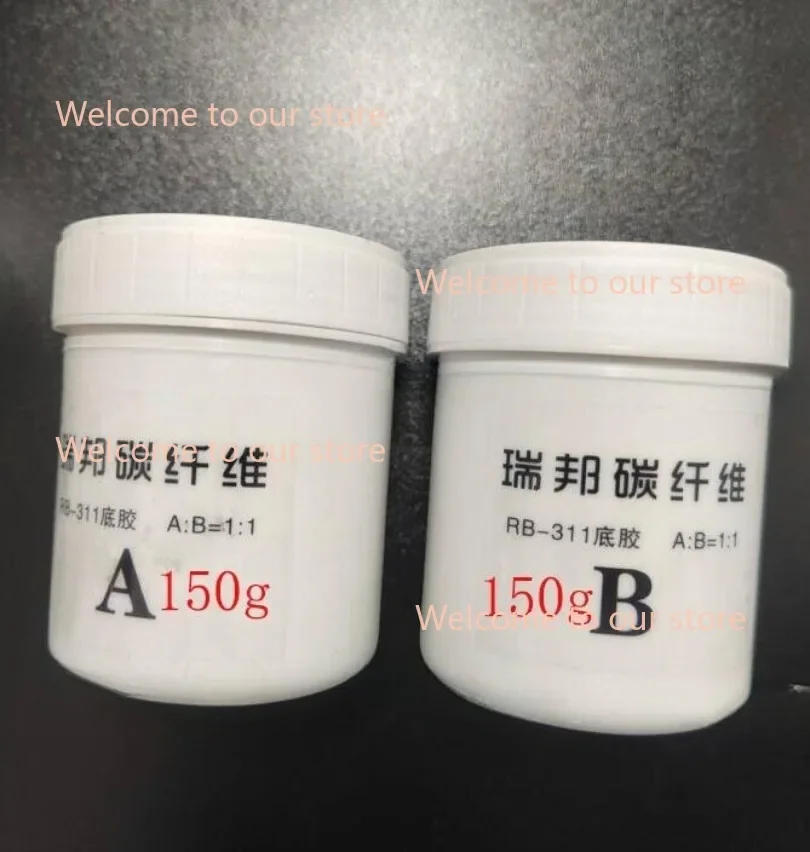

Condition:New: A brand-new, unused, unopened, undamaged item (including home made items). See the seller's ... Brand:Unbranded Color:Clear UPC:does not practice Country/Region of Manufacture:China Epoxy Carbon Fiber Glue Black Base Glue A 150g + B 150g For Car Craft Making DIY Shipping quantity: A 150g + B 150g Instructions to be used of carbon fiber coating primer Compared with some so-called quick-drying primers with low viscosity (quick-drying and brittle, and simple to delaminate after publicity to the solar in summer),The carbon fiber coating primer of this product uses E51 epoxy resin (A) and an progressed high bonding and excessive adhesion curing agent (B). It has some great benefits of nice toughness, stable adhesion, excessive peel resistance, and never clean to delaminate after being exposed to the solar in summer. This also is the original aim of our store to make a decision this mannequin as the carbon fiber coating base glue. However, some customers complained that the consistency of the bottom glue in our shop is too excessive (caused through low temperatures in winter), which may cause inconvenience in use. This article will introduce in detail tips on how to greater use carbon fiber-coated base glue. Scope of application: ABS plastic, aluminum alloy, iron, wood, ceramic (unglazed) and other polar supplies (i.e. supplies with painted surfaces or paintable surfaces) Special Note:First: Surface remedy of normal partsUse 320-grit sandpaper to dry-sand the surface of the wood object, completely polish the paint surface, and hold the outside as tough as possible. Then use a application knife to score the outside into a mesh to extend adhesion as a lot as possible.Second: Preheat to minimize viscosityWhen the temperature is less than 20°C, the viscosity of the bottom glue (B) will increase. When the temperature is lower than 5°C, the viscosity of the base glue (A) may also increase. At this time, it may be preheated to lessen the viscosity. Easy to apply in proportion. When the temperature is less than 5℃, (A, B) could be preheated at the same time. Heating the insulated water for about 10 mins will greatly reduce the viscosity and make it simpler to use.Third: ProportionThe coloration of primer (A) may well precipitate if left to face for a protracted time. Before mixing, you may open the bottle cap and stir it with a stirring rod a couple of times, or replace the bottle cap and shake it up and down a couple of times.According to A:B=1:1 (the quantity ratio and weight ratio are the same), take the share and combine very well earlier than use.Fourth: PaintingWhen painting, you possibly can approximately follow it first. After brushing, use the recent air setting of a hair dryer or the low setting of a heat gun to blow the whole floor for 2-3 minutes to additional lower the viscosity and control the thickness of the whole floor to a minimum.1: Use the new air atmosphere of the hair dryer, the non-adjustable low surroundings of the heat gun, and the adjustable setting of 150-180℃2: Blow the whole floor for 2-3 mins to further lower the viscosity3: Press the brush and scrape off the excess primer to achieve a average thickness (generally a similar thickness as normal A4 paper)4: After brushing, place it in the air. After a era of time, the skin might be level.Special reminder: When making use of primer, the brush should be pressed all the way down to allow the primer to fully mix with the original piece.Fifth: Waiting timeAfter making use of the primer, it's best to await a while to achieve the finest viscosity when laying the carbon fiber cloth.Please check with the ensuing for particular instances 0-10℃ (it is recommended to take warmth preservation measures under 0℃)----1.5-2 hours10-15℃----about 1.5 hours15-25℃----1-1.5 hours25-30℃----about 1 hour30-35℃----45-60 minutesBake at constant temperature 60-65℃ for 15-20 minutesAfter the appropriate time, the stickiness could be very good when touched along with your fingers, and it's going to look like a string, and you'll lay the carbon cloth.A be aware of caution: if the base glue is utilized thickly or if the time isn't always enough, the carbon cloth may seep out of the outside of the carbon cloth and influence the effect. Sixth: After laying the carbon cloth, the carbon cloth needs to be pressed firmly with the palm of your hand to make the carbon cloth solely match the original part. After urgent the complete surface, you would wrap it with plastic wrap and tighten it (keep it wrapped for 1.5-2 hours). Further let the carbon cloth fit the unique part. At this point, the whole strategy of utilizing the primer is over.Use the primer in keeping with the above method. After all is completed, the complete carbon fiber can be practically incorporated with the unique part, which can efficiently prevent edge warping and separation and delamination.

Recenzja

0 people rated this product

1SET Epoxy Carbon Fiber Glue Black Base Glue A 150g + B 150g For Car Craft Making DIY

Free shipping & returns

QWQER Express,

QWQER Express, USPS,

USPS, DHL

DHL

Shopping security

- Safe payment options

- Secure privacy

- Secure logistics

- Purchase protection